|

All

KRM fertiliser spreaders use our Trend spreading system. This system

is unique in combining two spread patterns for the ultimate spreading

performance in-field and at the headland.

|

|

In

Field Spreading

|

|

Headland Spreading

|

|

|

|

|

|

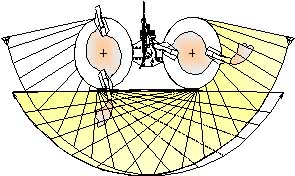

A

true "Double Double Overlap" spread pattern is used

for in field work. The large diameter stainless steel discs

rotate towards each other giving maximum accuracy and tolerance.

|

|

Simply

by reversing the discs the back of the vane is brought into

use. The natural characteristic of this pattern ensures a

sharp cut of at the headland.

|

|

The "Double

Double Overlap" spread pattern offers the largest amount

of overlap possible and therefore the highest degree of tolerance

when spreading.

|

|

The

diagrams below demonstrate that the left hand disc applies fertiliser

across the full spread width as does the right hand disc, therefore

a true double overlap tramline to tramline across the full width

has taken place.

|

|

|

|

|

| As

the machine spreads the next tramline another double overlap is applied.

It can now be seen that the area between the tramlines which has now

had its whole application has received 4 applications two from each

disc. In this way the spread pattern is built up little and often.

When spreading in the real world there are many factors that can affect

the evenness of spread, such as wind, uneven ground, material variations

and PTO speed fluctuations. By using the Double Double overlap system

where effectively 4 applications are being applied any external factors

will have a much smaller affect than they will with other spread systems

offering less overlap. |

|

| Tray

tests are regularly carried out by Bogballe the manufacturers who

have their own test hall. This is done to ensure the accuracy of their

machines and also that the spread charts supplied with machines are

up to date and include all fertiliser types. The diagram below shows

actual test hall data for a machine doing a tray test with only the

left hand disc spinning. As you can see an even triangular spread

pattern is achieved and fertiliser is spread across the full 24m spread

width |

|

|

|

The

next diagram in the sequence is showing just the right disc spreading

and again we have a very even triangular shaped spread pattern across

the full 24m spread width.

|

|

|

|

This

last diagram in the sequence shows the result when both disc's are

running together. The red line along the top indicates the overall

spreading result when the machine spread the adjacent two tramlines.

|

|

|

| The

diagram below shows what would happen if the spread pattern was overlapped

at different spread widths. It can be seen that at 24m which is our

target spread width the coefficient of variation (or evenness of spread)

is 4.5% an excellent result. What this diagram also shows is that

the accuracy of the machine is not lost if for some reason it is not

driven at 24m for example on grass. Where the actual spread width

may vary due to driving accuracy. It can be seen that the coefficient

of variation remains below 6% at all widths below 24m and only exceeds

10% at 28m. (Stripes start to become visible in a crop at 20%, KRM

do not publish spread charts for machines which give a coefficient

of variation worse than 10%). This highlights the tolerance the KRM

machine, all external factors such as PTO speed, sloping ground, material

size and wind, have the same effect in the field as driving at an

incorrect width. |

|

|

| |

| |